Berneck has a history dating back to its establishment in 1952.The company is headquartered in Curitibanos, Santa Catarina, Brazil. Berneck is known for its involvement in the production of wood-based products. This includes plywood and other engineered wood products. The company may also be involved in the production of MDF (Medium Density Fiberboard), an engineered wood product widely used in furniture and construction. As with many companies in the wood industry, sustainability and responsible forestry practices are crucial. Companies like Berneck often emphasize sustainable sourcing of raw materials and responsible environmental practices. Berneck likely has a significant presence in the Brazilian and possibly international markets, providing wood products for construction, furniture, and other industries. Successful companies in the wood industry often invest in modern technologies for manufacturing processes, quality control, and sustainability measures. Berneck might be incorporating advanced technologies in its production systems.

Wood Fiber Preparation: Design a process for breaking down wood into fibers efficiently.

Resin and Wax Mixing: Establish a controlled environment for combining resin and wax with wood fibers.

Forming Panels: Develop a method for forming panels under high temperature and pressure.

Curing and Finishing: Implement a curing process and finishing touches to ensure product durability and quality.

Optimized Heating System: Consider energy-efficient heating systems to reduce operational costs.

Waste Heat Recovery: Implement systems to capture and reuse waste heat generated during production.

Automated Inspection: Utilize sensors and automated systems for real-time quality control.

Testing Protocols: Develop testing protocols to ensure compliance with industry standards.

Waste Management: Implement a comprehensive waste management system for by-products.

Sustainability Measures: Consider sustainable practices in wood sourcing and production processes.

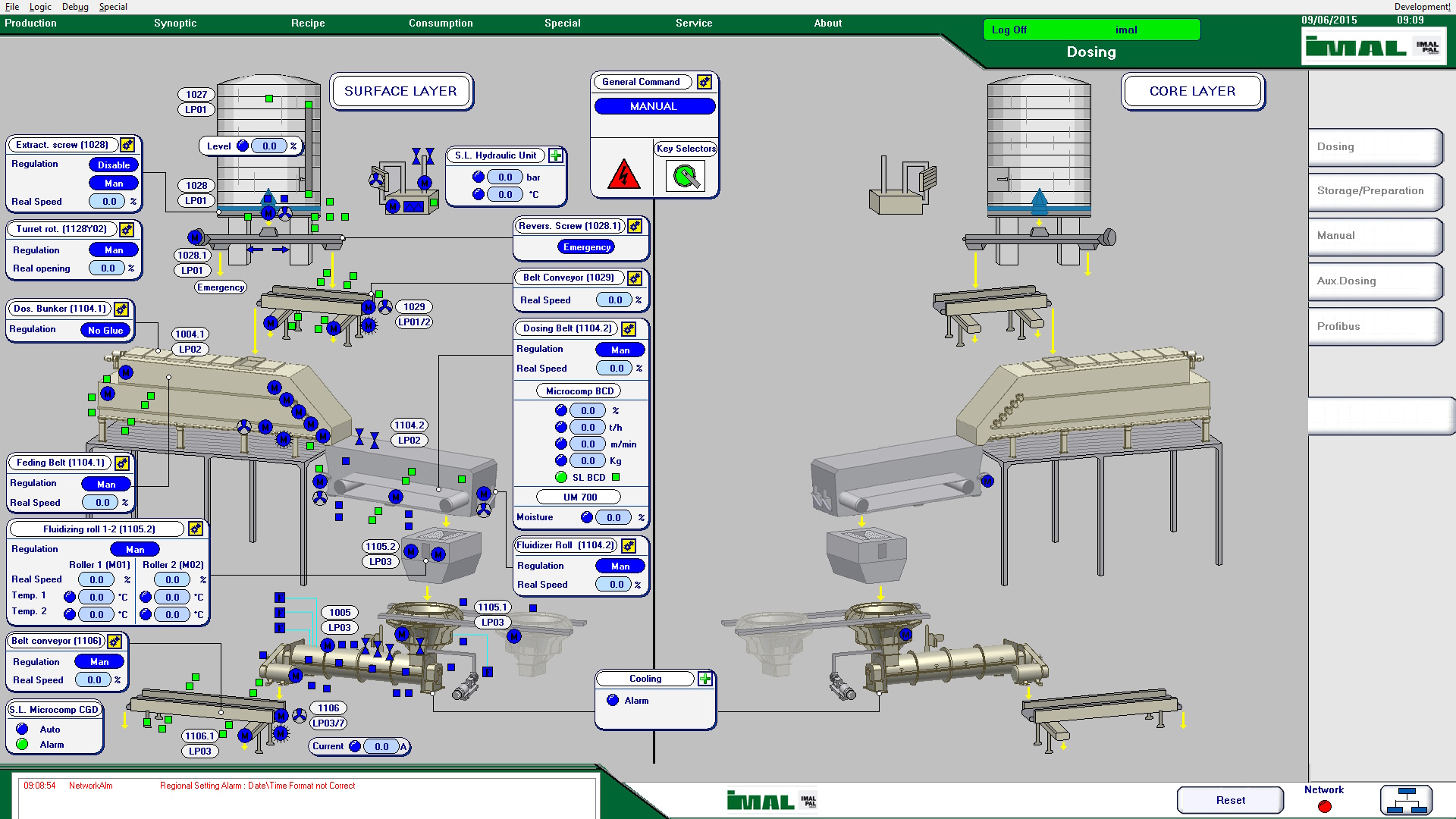

Industry 4.0 Integration: Incorporate automation and data analytics for improved efficiency.

Remote Monitoring: Implement systems for remote monitoring and control of the production process.

Environmental Regulations: Stay compliant with environmental regulations to minimize negative impacts.

Quality Standards: Ensure adherence to industry quality standards and certifications.

Operational Costs: Monitor and optimize operational costs through efficient resource utilization.

Summarize the key aspects of the MDF production system, highlighting its efficiency, sustainability and compliance with quality standards. The dosing control system for gluing components is controlled with an automatic PID system, furthermore the wood dosing process for production was carried out with a proportional control system based on the weight and speed of the dosing bunker. Provide recommendations for continuous improvements, such as exploring new technologies, expanding sustainability initiatives, and staying current on industry progress.

Thanks: With the collaboration of everyone, including electricians, mechanical fitters and external suppliers, the objective was achieved within the proposed times and with the optimal quality as per the contract.