COROB is an Italian company that has established itself as a leading provider of innovative dispensing and mixing solutions tailored for the paint and coatings industry. With a focus on precision and efficiency, COROB's technologies play a crucial role in enhancing the production processes of paint manufacturers and related industries. COROB offers a range of dispensing systems designed to accurately measure and dispense colorants, additives, and other materials used in paint and coating formulations. These solutions contribute to precise color matching and consistent product quality.

The process of filling paint cans involves several steps to ensure that the paint is evenly distributed and the cans are properly sealed. Here is a brief description of the process:

1. Preparation: First, the paint cans are cleaned and dried to remove any residue or contaminants. Then, the paint is mixed according to the desired color and consistency.

2. Filling: The paint is poured into the cans, taking care to avoid spills or splatters. The cans are typically filled to a specific level to ensure the correct amount of paint is dispensed.

3. Sealing: The cans are then sealed with a lid or a metal disk that fits snugly over the top of the can. This helps to prevent the paint from drying out and keeps the can clean and organized.

4. Labeling: Finally, the cans are labeled with the paint type, color, and other relevant information. This makes it easy for customers to identify the paint they need and use it correctly.

Overall, the process of filling paint cans requires attention to detail and a clean, organized workspace to ensure that the paint is evenly distributed and the cans are properly sealed.

Industry 4.0 Integration: Incorporate automation and data analytics for improved efficiency.

Remote Monitoring: Implement systems for remote monitoring and control of the production process.

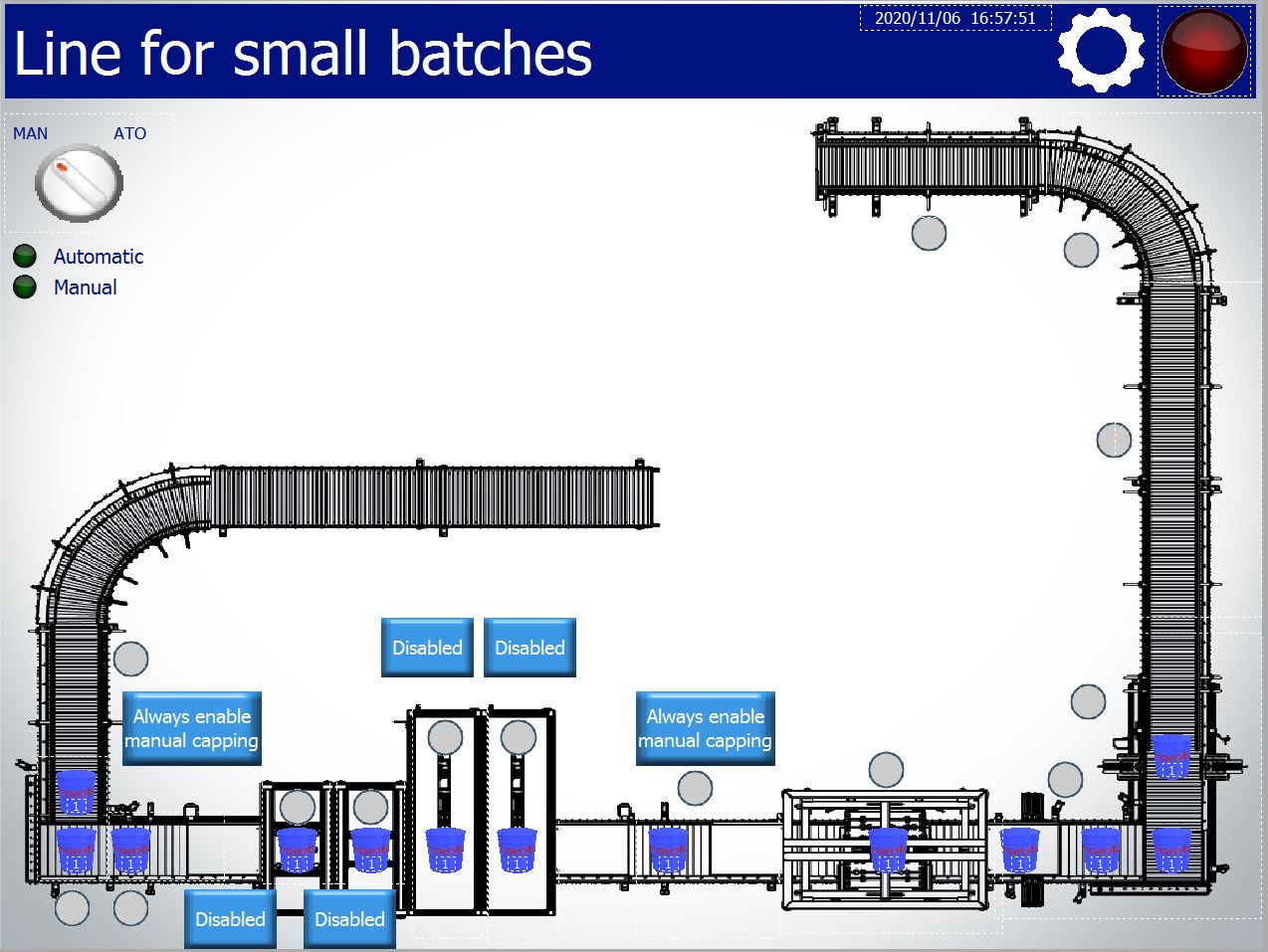

Smart filling system: The system was composed of a roller transport, with sensors that determined the size and material of each individual can, depending on the type of can, the system independently moved the stops of the product, sent the data for the quantity of filling and stopped at the correct capping station, furthermore, different types of cans could be inserted, given that the system was able to recognize their type. In addition to handling, I also managed the capping cycles and data exchange with the filler. The HMI (Human-Machine Interface) was implemented using WinCC from Siemens. Overall, the system was highly automated and efficient, with the ability to handle a variety of barrel types and sizes. The use of sensors and data exchange with the filler ensured accurate and consistent filling, while the HMI provided easy control and monitoring of the system.

In conclusion, the system described above is a highly advanced and efficient solution for the automated filling and capping of cans. The use of sensors and data exchange with the filler ensures accurate and consistent filling, while the conveyor belt system and HMI provide easy control and monitoring of the process. The ability to handle different types of cans and sizes makes the system highly versatile and adaptable to a wide range of applications. Overall, this system represents a significant step forward in the automation of can filling and capping processes.